Black Arts LSTR

-This is unverified – Hope to verify it this weekend.

There are some hard working people at Madbean forum that have been working on a great spreadsheet with a bunch of Big Muff variants on it. I wanted to contribute is some way and I found that no one has picked apart the LSTR for the list.

There was a schematic that was posted in FSB forums.

Mark over at Tagboard Effects made a vero layout for it.

Since we at the Madbean forums use the Mudbunny PCB as a primer, I have matched the parts from both the FSB schematic and the Mudbunny and this is what I came up with.

This is the BOM for the Black Arts LSTR built on a Mudbunny PCB.

| Resistors | Capacitors | Diodes | |||

| R1 | 1M | C1 | 100n | D1 – D4 | 1N914 |

| R2 | 39K | C2 | 560p | D5 | 1N4001 |

| R3 | 100K | C3 | 100n | ||

| R4 | 470K | C4 | 100n | Transistors | |

| R5 | 100R | C5 | 560p | Q1-Q4 | MPSA12 |

| R6 | 15K | C6 | 100n | ||

| R7 | 1K | C7 | 100n | Pots | |

| R8 | 15K | C8 | 560p | SUS | 100KA |

| R9 | 100K | C9 | 100n | TONE | 250KB |

| R10 | 470K | C10 | 1n | MID | 50KB |

| R11 | 100R | C11 | 10n | VOL | 100KA |

| R12 | 15K | C12 | 100n | ||

| R13 | 15K | C13 | 100n | ||

| R14 | 100K | C14 | 100uF | ||

| R15 | 470K | C15 | 100n | ||

| R16 | 100R | ||||

| R17 | 15K | ||||

| R18 | 68K | ||||

| R19 | MID POT | ||||

| R20 | 470K | ||||

| R21 | 100K | ||||

| R22 | 15K | ||||

| R23 | 1K2 | ||||

| R24 | 100R | ||||

Excel Spreadsheet in juansolo’s format

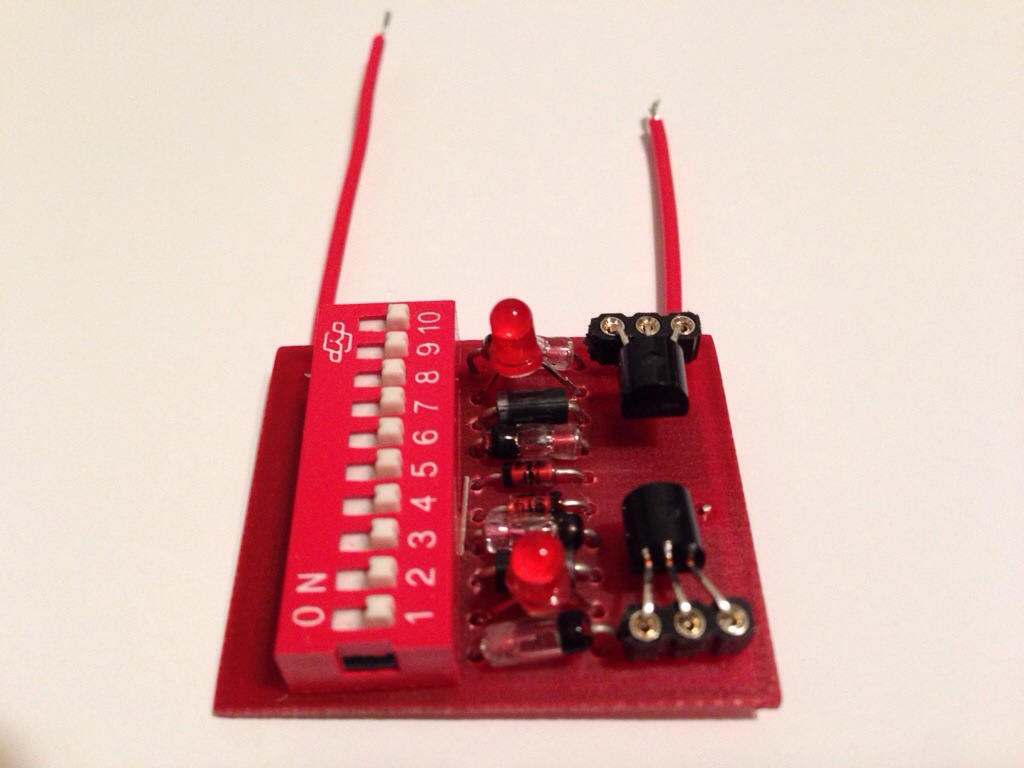

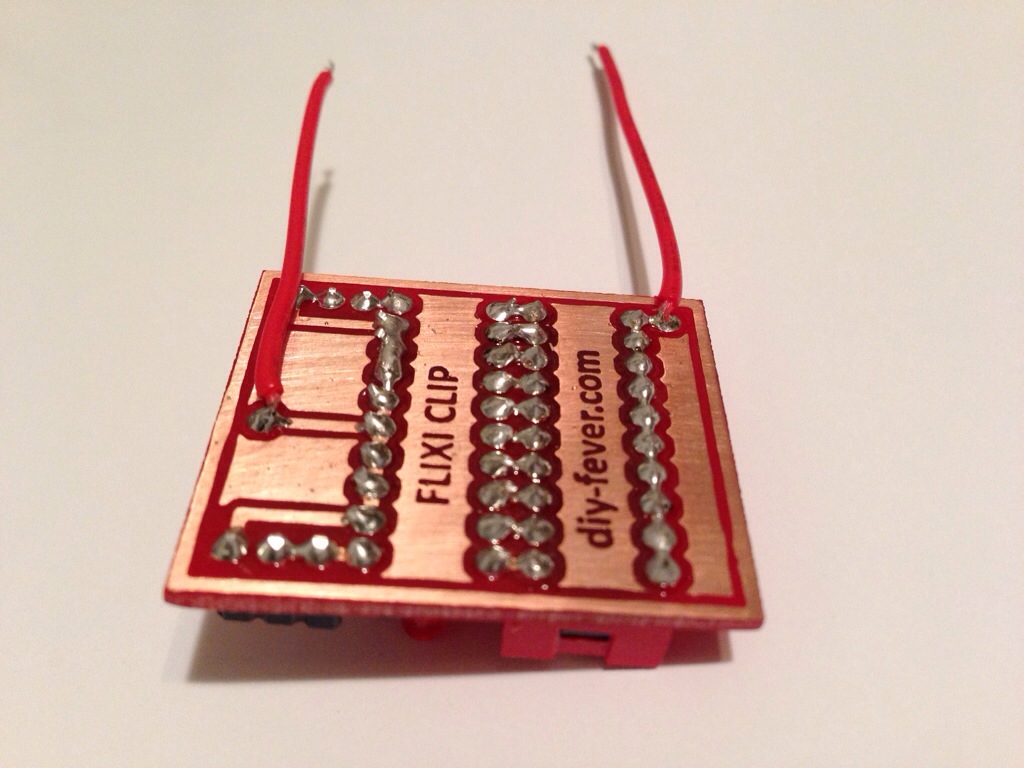

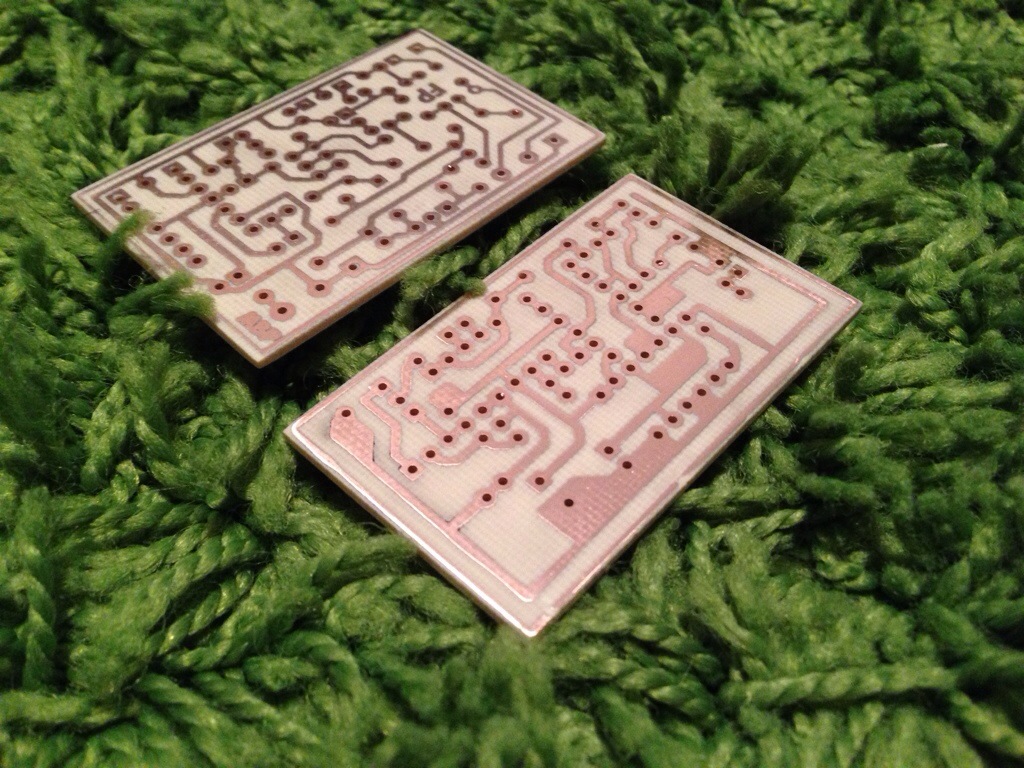

Update: populated the Mudbunny this weekend but I need to do the off board wiring. I hope to work on this tonight.

Updated:

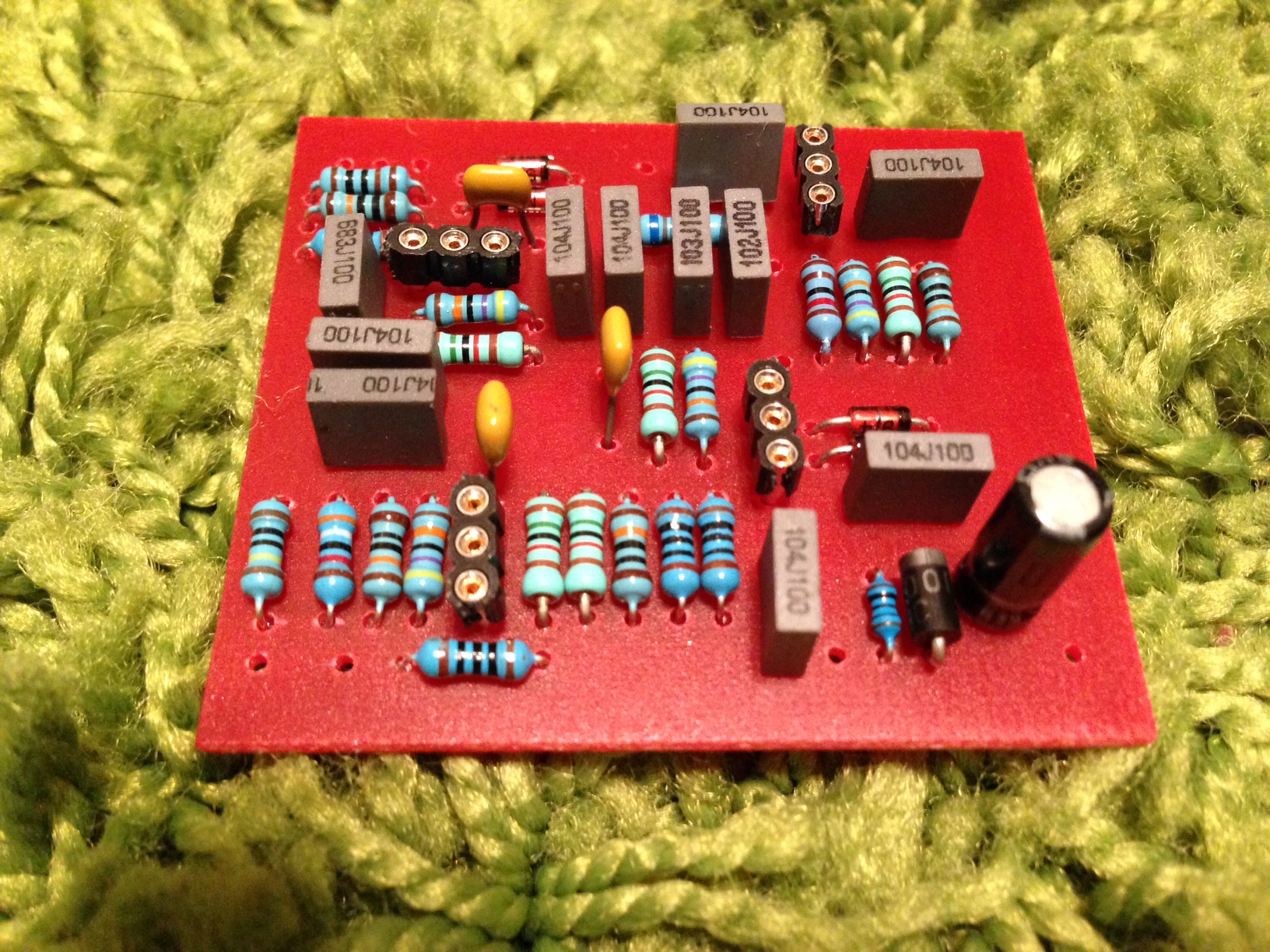

Populated