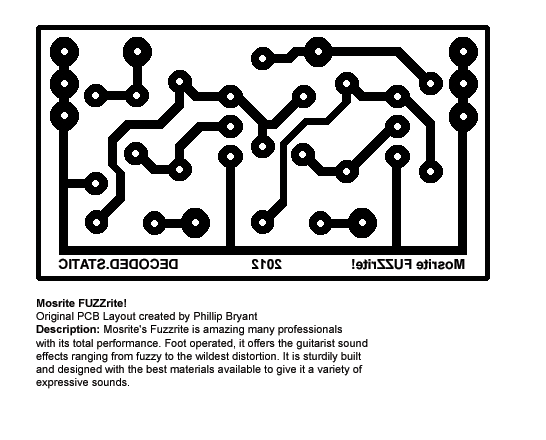

PCB etching attempt #2

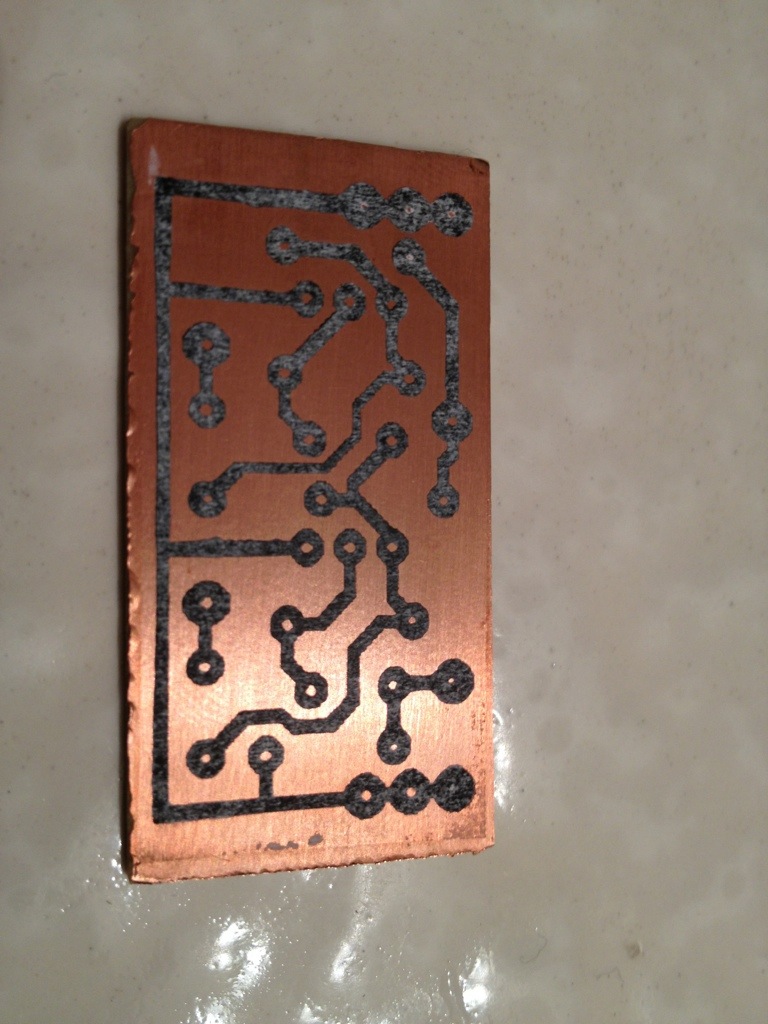

Armed with a new technique found online and some new glossy paper to do the toner transfer I attempt to try this again.

Items I needed:

- Copper clad board

- Laser Printer

- HP Glossy Presentation Paper (Office Depot $6.99)

- House hold iron

- Ferric chloride solution

- Plastic containers with lids

I then put it in a bath of the ferric chloride solution. I would “agitate” the solution every 3-5 minutes.

After I noticed that all the copper was removed from the clad board and all that is left was the toner covered traces. I then gave it a bath in water to remove any of the left behind ferric chloride solution.

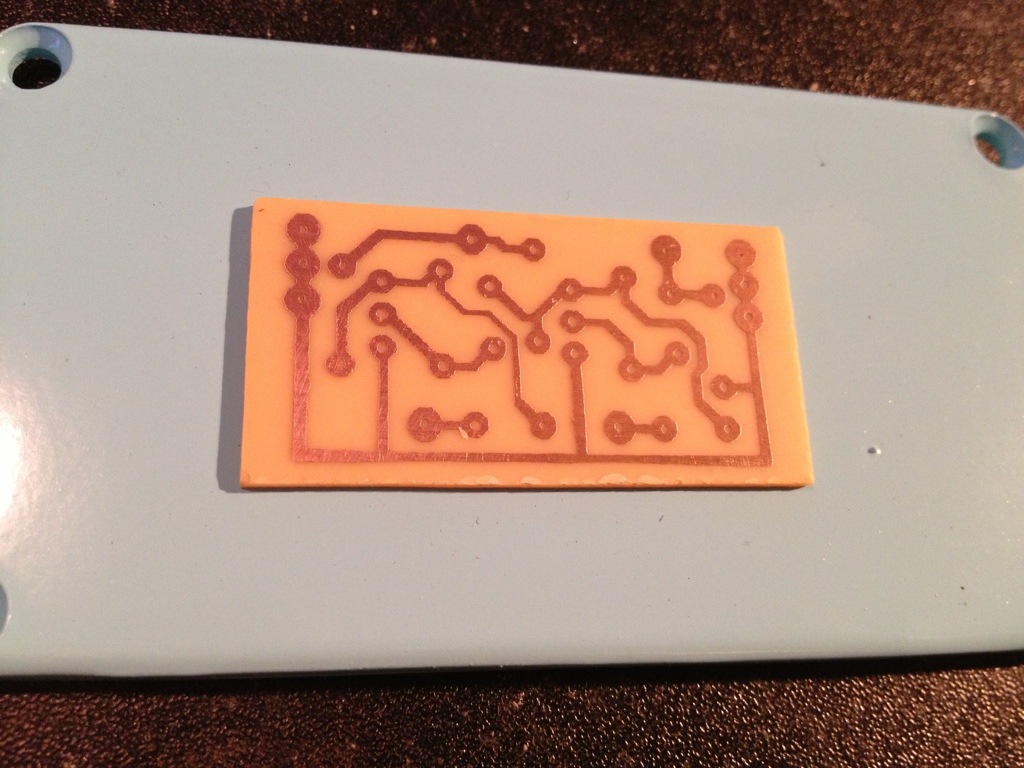

I then use some nail polish remover and abrasive sponge to clean off the toner and leave behind the copper traces. This is the point where it looks like a proper PCB.

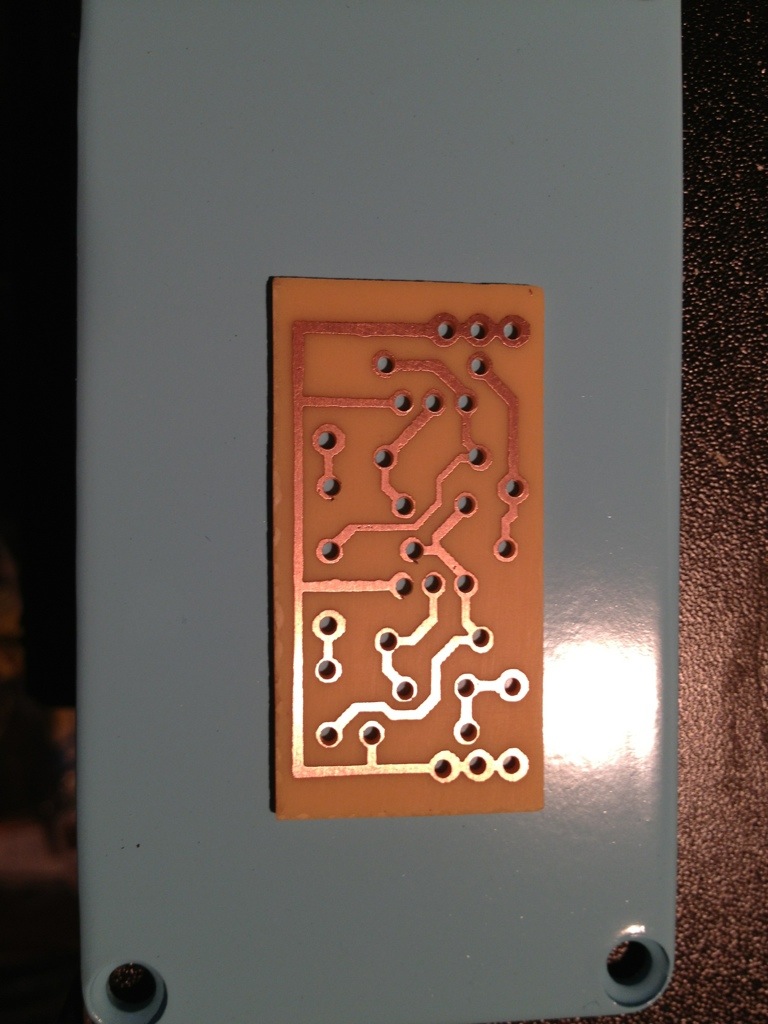

Then the holes are drilled for “trough hole” hardware.

The holes I drilled are WAY to big but it was all I had to test with. I will need to buy a proper drill bit for my Dermal. I just wanted to drill the holes with what I had on hand so I can go through the process to practice.

The ferric chloride solution is reusable and I just slapped a lid on the plastic container so I can use it to make other PCBs this week.

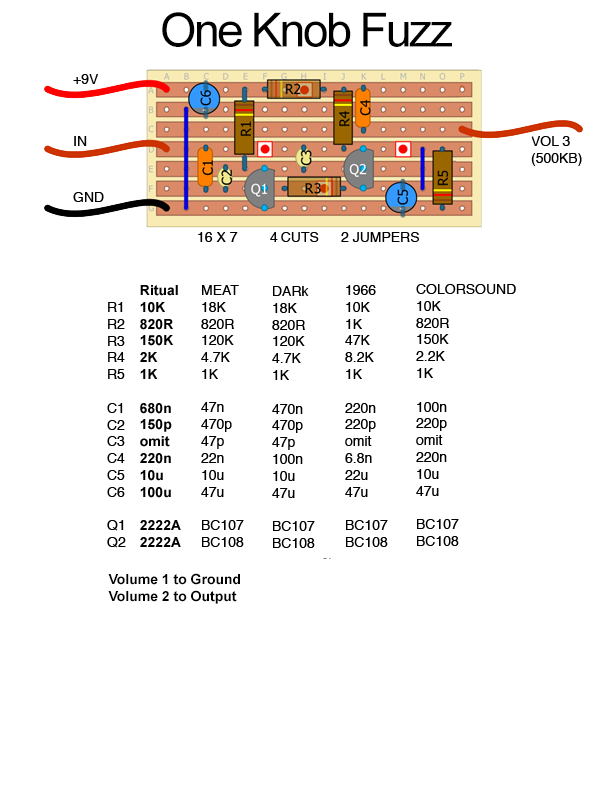

One Knob Fuzz’s

To list a few:

- DAM Meathead

- DAM Meathead Dark

- Italian Tone Bender 1966

- Colorsound One-Knob fuzz

- Black Arts Toneworks Ritual

Pulled this from Dr. Tony Balls on FSB

Someone took apart a Black Arts Toneworks Ritual and said these were the different values on the parts from the picture above.

There is other schematics with these pedals using transistors BC108 and BC109.

Paint template test

Label fail!

I attempted to make some art for a pedal I am working on (The Lovepedal Karl Fuzz) Everything started out great and the design came out great. I printed it out on my HP Officejet onto some waterslide paper. I did a seal of the artwork with some clear coat since the injet ink will come off in water. I let it dry and started the process, everything went well until I tried to remove air bubbles and the artwork just scraped off. I used my finger to remove air bubbles and not some abrasive tool. Well, I guess I need some more clear coat next time. Time to do it again.

Fairfield Barbershop OD Clone

Rustoleum Test

I did a thick coat of green hammered Rustoleum and topped it with a thick grey hammered Rustoleum and baked it at 200 degrees for 15 minutes and got this result.

This is just a test box but I plan on using this method. I think it would look better with the grey first then the green. I’ll try that next.

My first PCBs

Local Shops…or the lack of

It is so hard to find any parts locally. I am trying to compile a list of local electronics/service centers that deal parts and see if I can make a mailing list to just send a blanket email to all of them looking for parts.

- Sparky Electronic Inc. (559) 227-2986 sparkyelectronics@att.net

- Arbuckle Jack C Company (559) 264-6554

- Whitcomm Electronics (559) 294-0977