Mutable Instruments Module Tester

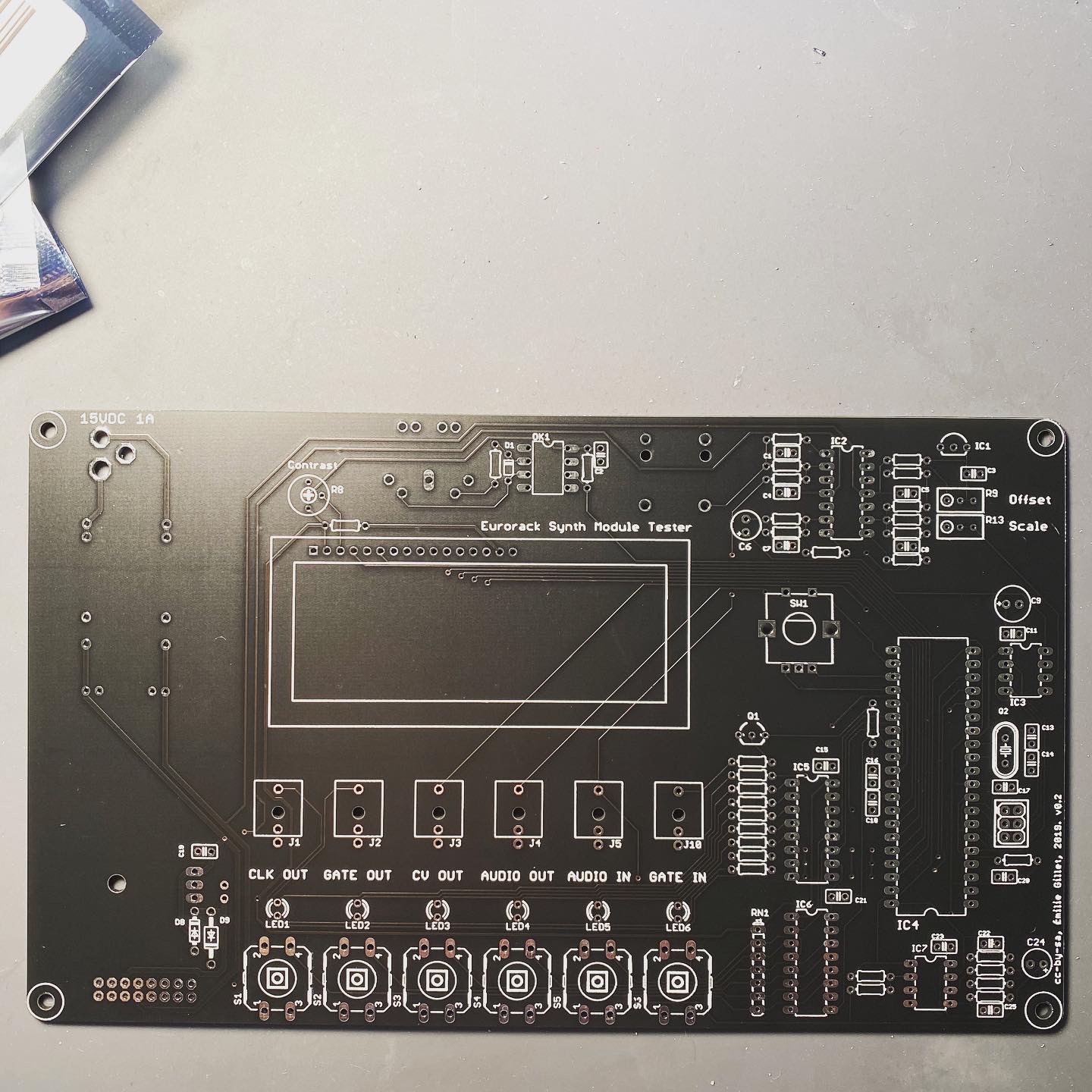

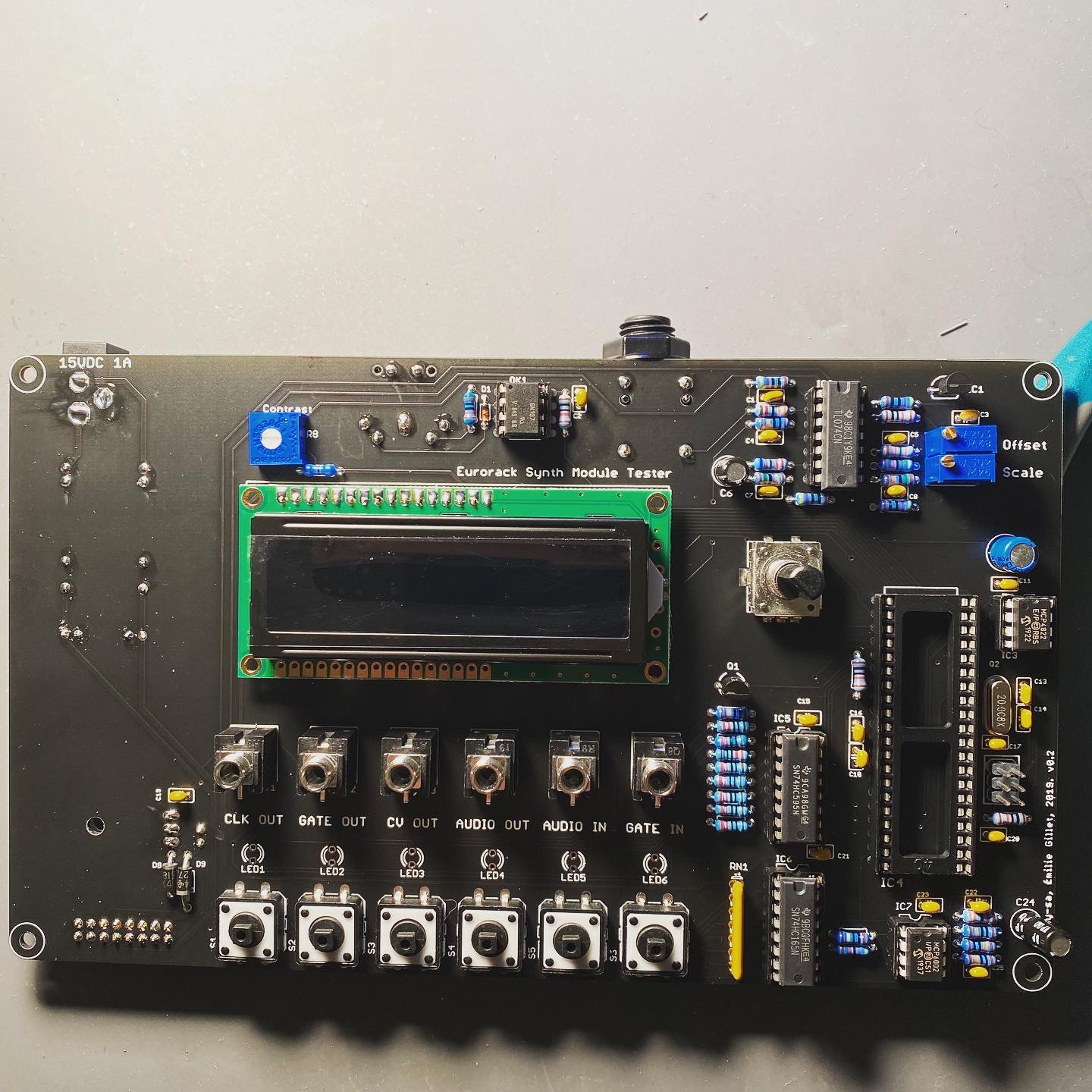

I wanted to build one of these when I first started my DIY eurorack adventure but never got around to it. I seen that the hardware got a revision recently and did away with the AC adapter needs and went with a more readily available 15v DC adapter. I had the PCB fabbed from JLCPCB and parts came from Mouser.

This utility is pretty straight forward. The ability to power your module you are troubleshooting off of this tester and to send various control voltages (waveform, LFO,notes,gates,clock) along with feeding audio & gate back into it will help greatly to pinpoint issues.

Resources:

- Mutable Instruments Archive page about the hardware

- Github for project

- Mouser cart for BOM

- Hex File

- EPS File for case

Flashing the AVR was pretty straight forward. Just needed to hook up the AVR ISP XPII, power up the unit and write the HEX file.

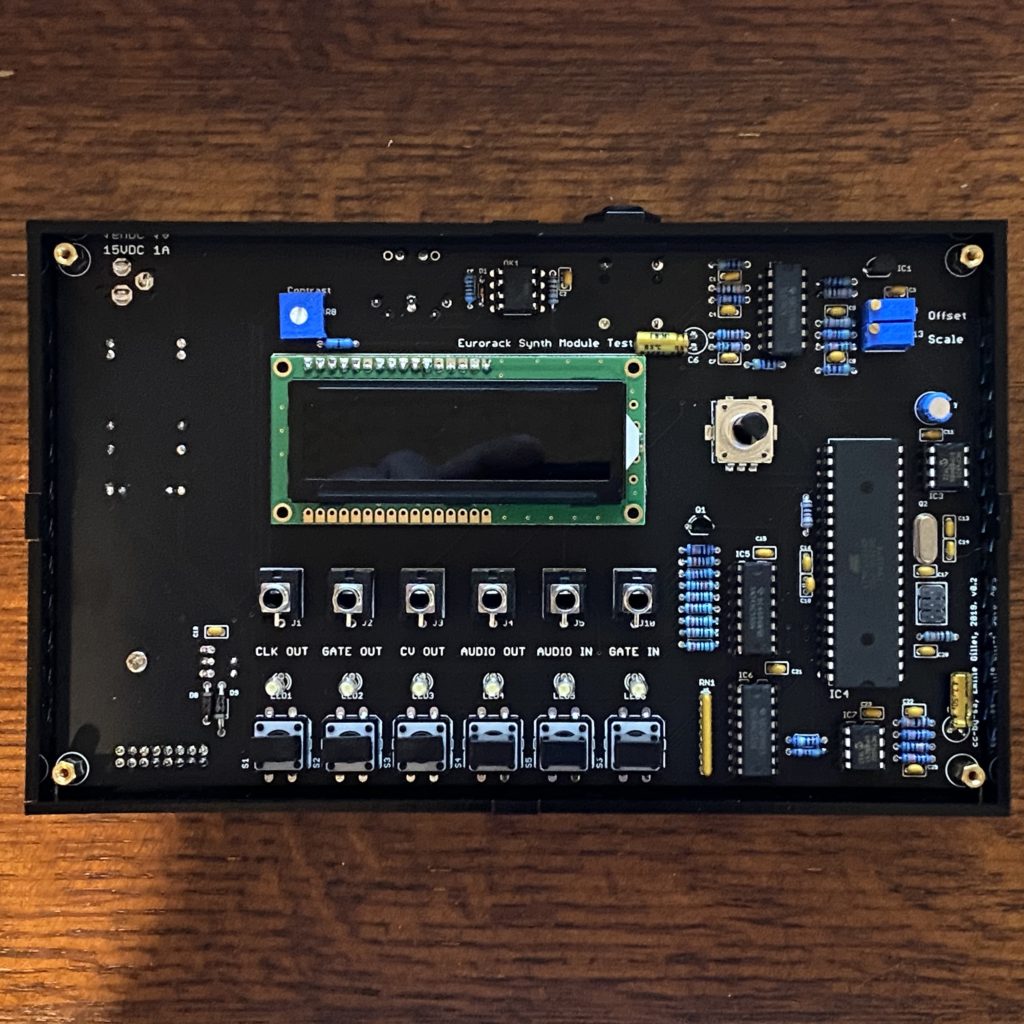

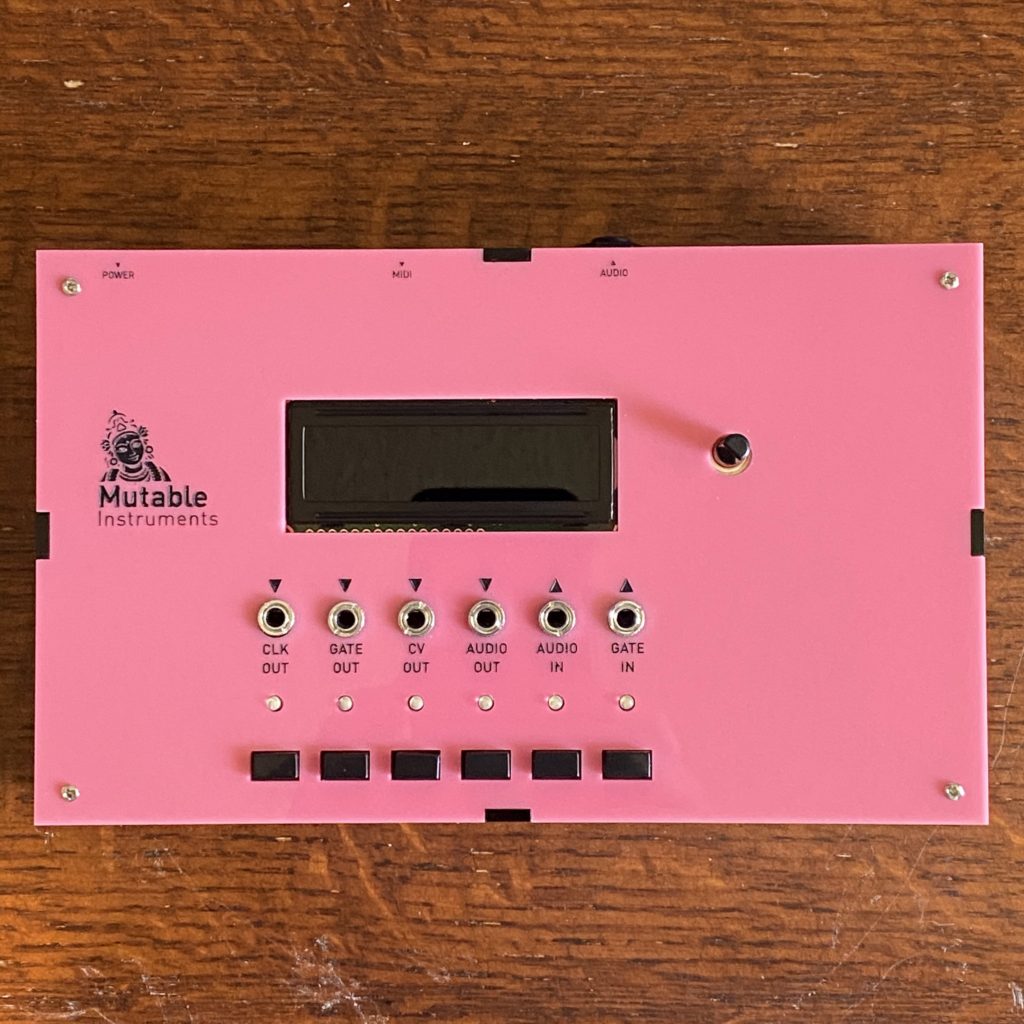

I used Ponoko for the first time to get the case laser cut and I think it came out great. I went with black sides and a pink top, cause why not.

Since the laser cut box came flat and had masking tape on it, I was able to spray paint the top black to back fill in all the text and logo. I was amazed how well this worked out.

Done, time to start troubleshooting some of my modules in my “box of fail”